August, 2025

The global market for processed sliced cheese is growing thanks to its convenience, portion control, and practical packaging. To enhance performance, Lasenor offers a comprehensive solution with two product ranges tailored for this purpose. The well-established SWISSGUM® D range helps adjust key functional characteristics in processed cheese formulations. Complementing this, the newly launched RELISER® SC range—introduced just yesterday—addresses slice-over-slice sticking with a release agent based on lecithin and vegetable oils. Together, these two solutions cover the entire process, from formulation to packaging, ensuring stable, functional, and market-ready cheese slices.

The processed sliced cheese segment is expanding globally, fueled by the growing demand for ready-to-use products. Sliced cheese makes up over 60% of processed-cheese sales worldwide, reflecting consumers’ and quick-service restaurants’ preference for uniform, easy-to-handle portions. Regions like North America lead consumption, accounting for about 44% of the global processed-cheese market in 2024. Countries such as Germany, the United States, and France are at the forefront of launching new sliced-cheese products, highlighting strong demand and innovation in this category.

These trends align with packaging innovations: consumers favor practical formats—resealable, easy-open, and freshness-preserving—even more than environmental concerns. Similarly, slices cater to busy lifestyles by providing ready-to-use portions without the need for cutting, aiding portion control and allowing for quick sandwich or burger assembly.

In 1911 in Switzerland, Walter Gerber pioneered processed cheese by grinding Emmental and blending it with sodium citrate, producing a smooth, uniform product that remarkably kept its texture once cooled. A few years later, in 1916, James L. Kraft in the United States patented a sterilization method that stopped natural ripening and allowed for true industrial-scale production; by 1950, he had introduced the first commercially stable cheese slices to the American market. Together, these innovations created a low-cost, highly reproducible food with a long shelf life that still provides controlled, reliable melting behavior.

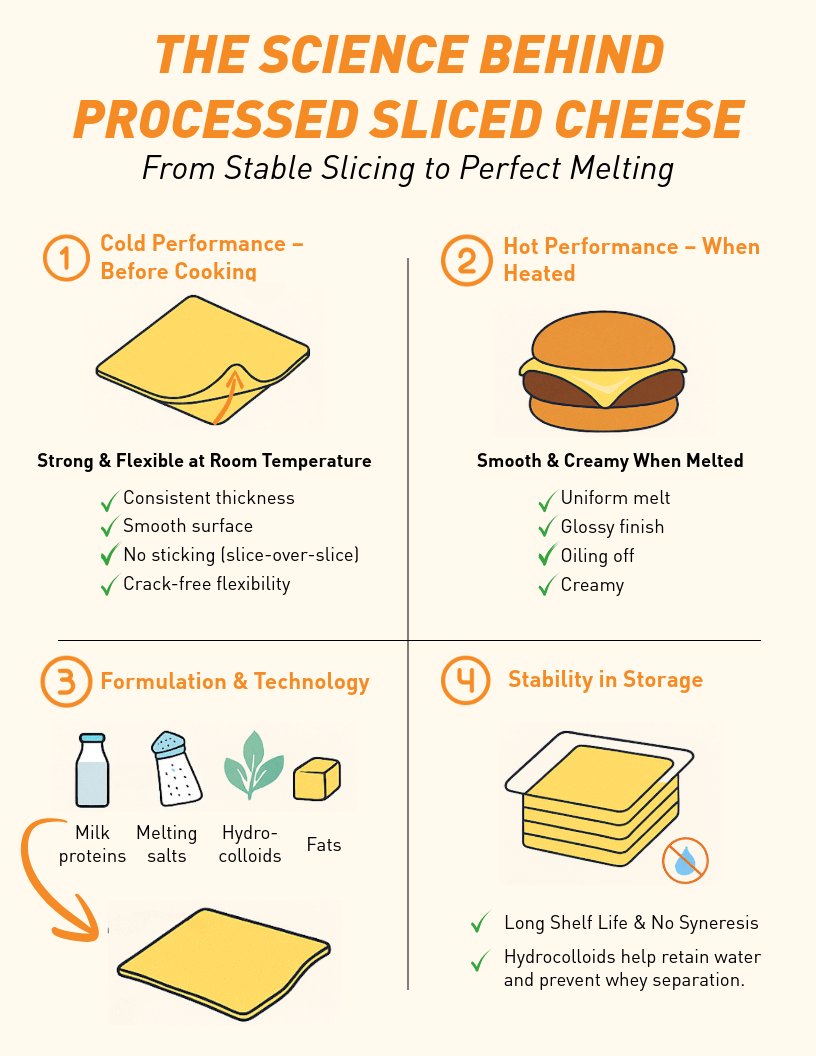

Processed slices have become essential in the food industry due to their advanced technological features. Unlike many natural cheeses, processed slices melt without fat separation.

In fast-paced industrial SOS settings, technical challenges include slicing and stacking quickly without sticking together, maintaining shape, and being easy to separate during packaging.

Achieving the ideal slice texture depends on the right stabilizing system. Lasenor’s SWISSGUM® D formulations are crafted to provide the desired structure for each application. These systems incorporate natural hydrocolloids such as:

Slice adhesion can stop production and reduce quality in continuous SOS slicing lines. To address this, Lasenor’s RELISER® SC release agents form an edible, ultrathin barrier on each slice’s surface, preventing sticking. Made from high-purity vegetable lecithin (sunflower or soy) combined with food-grade vegetable oils, RELISER® SC is applied by spraying or rolling during slicing. The invisible film prevents adhesion without changing flavor, appearance, or aroma.

Operational benefits include:

Meeting modern market expectations for convenience, sensory quality, and sustainability requires a balance of formulation and processing. Lasenor provides an integrated, expert solution: SWISSGUM® D functional systems for customizing texture, elasticity, stability, and melt; and RELISER® SC release agents to enable industrial-scale manufacturing without sticking. Together, they help sliced-cheese producers stand out with superior products—in taste, texture, appearance, and ease of use. Lasenor’s complete portfolio of functional ingredients and processing expertise to “shape the perfect slice” that the global market demands.

Article Sourced from Lasenor